Editor’s Note: This is a long-format interview that easily runs to twice the length of the usual InsightEV post. It is longer than the standard email length allowed, and you would need to jump to the website midway. However, every word from Jay and Derek is gold, and we strongly urge you to grab a coffee and give this a good read-through.

We recorded this a few days before Jay Giraud was replaced as CEO. However, that did not change the substance of the interview, so we decided to run with it.

Damon Motors just went public a few days ago through a listing on the NASDAQ. This is a significant event for the E2W industry. Damon is a tech leader at the top of the pyramid, and their success (or not!) sets the trend for the rest of the industry.

A few days back, we sat down with Jay Giraud, (now ex) CEO of Damon Motors, and Derek Dorresteyn, the CTO, to discuss their stories and what makes the Hypersport special.

Hi Jay and Derek, Welcome to this InsightEV interview. Just so you know, you guys are the first long-format interview we are doing for InsightEV. Damon has always been an impressive yet intriguing case study for us. Apart from the monocoque battery pack, the high-speed motor, and the 200 mph top speed capabilities, what we admire about the HyperSport is its very competitive weight. So, without wasting time, we want to hear your vision for Damon and what makes the HyperSport special.

Why did you guys start by attempting the most difficult part of the equation? A supersport liter-class equivalent motorcycle is the Holy Grail of motorcycling, and you guys went there first?

Jay Giraud (JG): In my previous startups, I learned that emotional decision-making always triumphs over logic. People believe that they are logical and rational. But human beings make logical, rational decisions that support an unconscious emotional bias.

With Tesla, we have seen that the path from exotic cars to expensive premium sedans to expensive premium SUVs and so on was right. You develop something that can be reduced in cost and power much more easily than trying to go up the pyramid.

Every other electric car company before Tesla failed. Why?

They were all a failure because they made cars inferior to whatever people owned in their driveways.

An inferior electric car does not inspire the mass market to switch from gas to electric because, as much as people think they want to do the right thing for the environment, they won't do it if it's a trade-down.

So that means if we're going to get the mass market, people who own top-of-the-line Ducatis, Hondas, Yamahas, KTMs, MV Agustas, whatever, to get those people to trade from gas to electric, the bikes have to be better. A lot better.

That meant making a bike that was better than anything in the world.

Of course, if we're going to do that, we don't want to be a one-hit wonder. So, we need to engineer a platform that can be rapidly expanded to many motorcycles beside and below the HyperSport.

That was the strategy and the rationale for starting at the top of the pyramid.

So, if we're going to do it, it better be a brand for which we can create enormous tailwinds—shift the sentiment of the marketplace with something so exciting that even people who don't see themselves owning an electric motorbike have to have it—they irrationally, emotionally have to have it.

Derek Dorresteyn (DD): Building a company from scratch is incredibly difficult because you're building all the pieces to produce, distribute, and build a brand and reputation. Damon started at that.

That pinnacle of motorcycling - not only to build a brand associated with performance and something very high profile. It's also the perfect way to demonstrate the performance of electric power if we could attack the part of the market with the peak gas performance.

Everything below that pyramid is then also achievable.

If you're developing a liter-class equivalent electric superbike, it is not just about the motor or the battery capacity. Every other component has to be upgraded and fine-tuned to match the powertrain. How did you go about it?

DD: The first step is to understand the existing product offerings. So, I created a MATLAB-based physics model of a superbike using the power, transmission, maths, and height of the center of mass—all the physical characteristics of a superbike. I mostly used publicly available information then and understood the Newtonian requirements.

These are the requirements for an electric drivetrain that could do that. It's an iterative process, but you eventually know you need a motor that does this.

We need a battery. That's about this size. If it can discharge at this rate, these things have to weigh about this much.

We need an inverter that does this much power and can spin a motor this fast.

That study led us to the rough requirements for a drivetrain, which were refined over time as we entered the details into CAD and started understanding the physical constraints.

JG: We can't build an electric superbike without the power and speed of a top-of-the-line Ducati or BMW.

I had a pretty strong hunch that, even with rapid charging and all the availability of charging then and where we thought it would go, we would need at least double the range of a gas-powered superbike.

I live in Vancouver. I may need to go from Vancouver to Whistler and back on a full charge where my friends on their equivalent gas bikes could fill up in Whistler.

Because this has to be a bike, I can ride with my friends who don't own Damons; I've got to look cool and go as fast as possible. But I must be able to go twice as far, which led to the 200 horsepower, 200 mph, and 200 miles of range equation.

DD: I could put these drive cycles in the simulation, and we could estimate the range, which would become more refined over time.

JG: It was a leap of faith to estimate where battery density would go and when the cost would come down so that you could effectively get the right energy density and find room for all the electronics.

DD: We based the initial design on cells that had yet to be released. They were on a road map, which is risky because sometimes schedules are delayed.

We bought a couple of competitor bikes, one from a famous European company and one from a famous Japanese company, and we took them down to the bolts. We took everything apart and studied how the chassis went together. We measured everything—the stiffness of the chassis and the ergonomics—and we refined our design based on those studies. Eventually, we were able to resolve this in the virtual CAD world.

We had development ongoing for some of the drivetrain components that we couldn't buy off the shelf, which was nearly everything. That included the inverter, the motor, the charger, the DC-DC, the BMS, the battery, the body controller, and the dash.

Our requirements exceeded what the market was delivering.

We have an incredible suite of technology in the vehicle, including an LTE cellular connection that allows data from the motorcycle to be pushed into the cloud. We've also developed a whole cloud back end for our data management.

The vehicle has OTA updates. The collision warning system has also continued to be developed.

With the drivetrain and all these things in development, we've measured the competitor motorcycle the CAD is resolving.

We've reached the point where we built several initial prototypes, and this isn't what we'd call a proof of concept prototype. The latest is an engineering validation prototype, where we have all our functional systems and designs. They're on a motorcycle that's not quite the production vehicle, but it's very close.

We then had to benchmark against the competition.

We picked the 2023 BMW S1000RR because it has a reputation for having the very best rider aids and the best integration of technology in a modern motorcycle. It's safer, easier to ride, and more accessible.

JG: …which are the qualities of an EV motorbike?

DD: These are really good qualities for us to benchmark against. So, we outfitted both motorcycles with industrial and automotive data acquisition systems and went to the track.

It was pretty special. By the second time around the track, our test rider, Kurt Risic, also a vice president of engineering at Damon, was riding wheelies down the front straightaway at about 130 mph. He was ecstatic.

We had confidence that we needed to commercialize this because we'd got something.

JG: At that point, considering the time, energy, and money that had gone into the development, you must go very far into design before you can even test. With our engineers, we had invested tens of millions of dollars and 2 1/2 years of development before we even got to put the thing on the ground and ride it.

Where did the inspiration for the HyperDrive come from? As you know, previous EV motorcycles didn't have structural battery packs.

JG: Derek and I intuitively believed that was necessary for the future. You saw it in ICE motorbikes, where the engine was used as part of the frame.

DD: The monocoque chassis concept is a product of design philosophy. If you need to meet a certain performance requirement (in this case, the performance requirement was to meet or exceed the superbike), you have to.

You have to make your best effort to reduce materials and costs and increase available packaging space in any way you can, and this is an offshoot of that philosophy.

JG: Yeah, well. This is one of the very discomforting thoughts I kept to myself in the first years of Damon. When you're interfacing with hundreds of investors, we are doing the dead opposite of what Silicon Valley insists that we do. This was the antithesis of MVP (Minimum Viable Product). You cannot build a superbike with an MVP philosophy.

DD: The MVP is the superbike itself.

JG: If it's going to do what a BMW superbike can, you cannot take an MVP approach. You have to take a big OEM approach, but with all the restrictions and nimbleness of a startup.

DD: Another important aspect of our process is building something that can be manufactured, scaled, and hit a BoM target. That's the strength of my background. I approach each part with a mental image of how the material will flow through a supply chain and onto the production line.

How is that going to be assembled? A high-volume manufacturing process will be used, and we'll need to control that quality, etc.

JG: You have to have a visual map of how this is going and how designs A, B, or C will move from an early prototype to a production process that can be scaled and cost-reduced. Not having that knowledge and experience, you end up in prototype hell where you can't get out of this flywheel that's working against you.

It is almost a flywheel of iterative prototypes that never mature into a production design without enormous amounts of time and money.

We wouldn't have succeeded with that approach.

DD: Other new companies struggle with this. They utilize methodologies to quickly make prototypes that don't translate into high-volume manufacturing and hit a wall where they must redesign everything.

We have embraced engineering with a Design-for-Manufacturing (DFM) process from day one. Our initial CAD had mold drafts in every part. That's how we work.

JG: This HyperDrive can scale to more than just a supersport bike, which is interesting engineering.

Yep, that was my next question.

JG: That's an interesting engineering constraint, or call it an engineering requirement, because you are going to bolt on different fork systems, different suspension systems at different rakes and trails, with different levels of travel and different lean angles—minimums and maximums.

You know, a touring bike on HyperDrive rides the way a touring bike should without compromising how a superbike rides on the same platform.

But they're both HyperDrive on the inside, in a closed system that bolts and mounts together uniformly.

Then, layer on the need for easy maintenance of those in the closed system.

DD: From day one, we were required to build a motorcycle platform from which we could build other motorcycle models. We anticipated what some of those other motorcycles would be - adventure bikes, more standard upright motorcycles, etc.

So, we surveyed the geometries of those motorcycles, overlaid this on the CAD, and confirmed that this system could be. We configured it to work for a wide range of motorcycles, and you know, honestly, this is the foundation from which Damon is being built.

If we just had a superbike, it would probably not be enough to sustain a company like Damon. We will need additional products.

JG: It's a small market. So people are like, why are you doing a sport bike?

But it’s like:

Nothing leans farther than a sports bike.

Nothing comes closer to the ground than a sports bike.

Nothing needs to go faster than a sports bike, etc.

So again, back to the pyramid.

Like the spear's tip, the superbike sits at the very tip. Following behind the tip of the spear is the rest of the spear. In this case, it's every other motorcycle you can imagine.

DD: As we commercialize the HyperSport, which we're doing as we speak, the components that get tooled up in mass production will decrease in cost as the volume increases. These other vehicles will take advantage of this initial investment in this platform.

The weight becomes challenging when you do a supersport equivalent motorcycle with a 20 kWh battery. I've seen that even with the battery-as-a-structure element (that Damon has), I think there are about five or six more motorcycles in the world that now have similar engineering methodologies. Still, I find all of them quite hefty. So, what does Damon do differently?

DD: Our focus on mass reduction has been a little more extreme than everybody else’s.

JG: The other companies didn't develop everything from scratch. We removed all the enclosures and went to high-tech, 3-millimeter structural walls.

So it's it's back to the the thesis of HyperDrive itself.

DD: We have a couple of advantages there. One of them is that we've co-located all drivetrain electronics inside HyperDrive. So we're talking about the inverter, the charger, connectors, DC fast charging connectors, and the charge port itself.

JG: The ECU's wiring harness.

DD: All those internal harnesses—everything is inside the HyperDrive. Suppose you take the traditional automotive approach to building an EV drive system. In that case, all of those systems are in a separate box sealed with sealed connectors and cables connecting them all in this distributed system. By putting them all in HyperDrive, we've eliminated all those boxes and sealed connectors.

So, our system is inherently simpler and, as a result, has less mass.

JG: Fewer parts, less mass, higher voltage, lower cost components, lighter components, and, as a result, fewer enclosures, integrated design.

DD: The integrated design also includes having one ECU perform multiple functions, so we have fewer ECUs, etc.

When you're designing all of the electronics from scratch, you can do that. But you have difficulty integrating all of those when you hire a company to sell you an inverter and another company to sell you the dash.

They talk poorly together, and you're stuck with what they offer instead of what you want.

JG: It's back to the incorrect perception that buying is better than making. Often, people rely on popular knowledge that isn't necessarily experienced and educated knowledge. Just because the auto industry traditionally procures from outside parties doesn't mean that's the better way.

Car companies don't save much money when they build cars. They do it with massive budgets, so you inherit the problems of systems not designed for each other, with extra enclosures, components, and parts. When you're developing a car, it doesn't matter much, even if it ends up being 200 pounds heavier.

On the other hand, if a motorcycle is 10% heavier than intended, it will have a massive range, speed, and performance penalty.

Developing from scratch is harder and riskier because you must develop the in-house capability to integrate all these disparate systems. But you can do anything if you hire great people because your vision and mission inspire great people to join your company. Then, ultimately, maybe it is or isn't the MVP way, but our requirements dictated things that weren't available off the shelf anyway.

DD: We're at a period in the EV industry where consumer acceptance is growing dramatically. The availability of vehicles is growing.

But the industrial side of this, the manufacturing side, the knowledge—right, it's still not nearly as mature as we are in the internal combustion engine world.

It’s not like incremental changes are happening. Much larger changes and improvements are occurring within the systems and components that make up the EV drivetrain.

When you buy something from an existing supplier, like a motor, within the supply chain, it probably has a five- or eight-year history right where it was conceived. It's now commercially available.

But thinking has progressed since then, right? Material science and all of the things that drive higher performance have progressed. We're at a point where progress isn't one or two percent yearly. Things can have steep function changes and big improvements; our motor is an example.

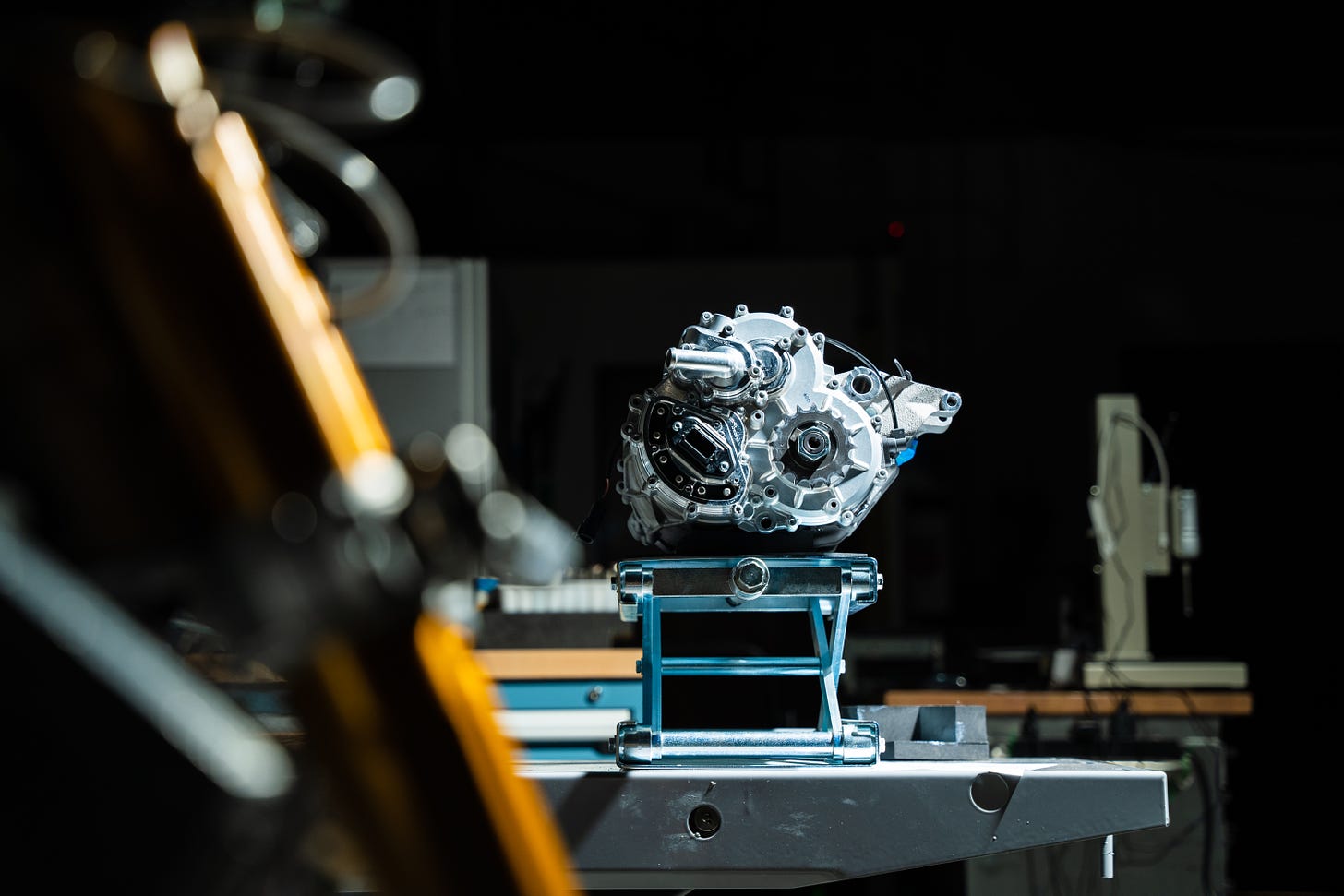

We have a motor that weighs 32 kilos, including the integrated gearbox. We made the motorcycle's peak power 150 kW, and we tested this motor up to 180 kW. It makes 200 Nm of torque at the rotor, but we multiply that 2.5 times through a high-speed gear reduction, so we make 500 Nm at the output shaft.

All of that's very high performance in a small package. We're achieving that through some pretty sophisticated cooling strategies. So, we have a water cooling loop around the outside of the stator, which is a very common strategy. Then, we also have an oil spray on the motor's interns, representing approximately 40% of the copper in the motor.

It's where the copper goes out of the end of the motor and does a 180-degree loop, then back in to create the coils that drive the electromagnetic machine. Cooling the ends can release more heat—an area that normally isn't connected very well to the coolant loop. That heat is, for the most part, the limiter of torque output in a motor.

By improving that heat transfer, we can drive a higher continuous and maximum output from the motor and achieve these numbers that, within automotive, are quite exceptional once again, also a high-speed motor.

We're spinning this motor to 18,000 rpm and utilizing some of that pressurized oil to keep all those mechanical components happy at high speeds.

So coming back to the motor, that's 500 Nm at the output shaft, and then you have a final drive. What is the ratio there - 4:1?

DD: The final drive ratios are more like 3:1. We've mapped the force at the tire patch and looked at it compared to the ICE machines with their sequential transmissions. We've also looked at it compared to the maximum force we can apply before wheel slip in optimal conditions. We have a machine equipped with a traction control system, wheelie control system, ABS, and all the sophisticated rider aids, and those are helpful in a machine that could break traction even over 170 kph. We have a lot of available force to drive the machine forward.

(That makes it 1500Nm at the rear wheel for the Damon HyperSport at peak. A comparable liter-class superbike like the BMW S1000RR puts down 1308Nm at the rear wheel )

Regarding the ABS, did you guys go to work on it in-house, or is it with one of the leading suppliers?

DD: I'm interested in working on it in-house at some point, but back to the MVP comment in mechanical hardware design. The MVP is just reducing the number of things you dig your teeth into, and we did not do that (the ABS) from scratch.

We're working with one of the big German companies that is quite knowledgeable about the topic.

JG: You know, like suspension systems and braking systems. There are things that companies make that are exceptional. They do just that, and they're the brands that buyers expect on a Ducati, they expect on a BMW, and they'll expect it on a Damon when they're paying USD 30,000 for a motorbike.

Certainly, we aren't trying to reinvent suspension or tires or things like that.

Returning to the HyperDrive, you said it is a monocoque, right? If I remember correctly, you told me long ago that it's like a clamshell that closes together many components.

DD: We have two large high-pressure die castings (HPDCs) that come together and enclose most things, and then two other covers go on to those. The additional covers allow access to power, electronics, chargers, inverters, and other components for service if required. The two big die castings are part of a movement in automotive technology back to integration. You take systems that traditionally might have many components and incorporate them all into a large casting, as Tesla has famously done with what they call it.

JG: Mega-casting.

DD: It's a way to capture a lot of structure but incorporate multi-axis CNC machining to create precision and a bunch of mechanical mounting points. So, it's a very effective technique for doing many things simultaneously with low mass and cost.

Finding a supplier capable of making a casting as large as that was complicated, though the number of suppliers versed in large castings is growing now because of more demand, but it's still quite limited.

JG: Still, very specialized.

But yeah, so these are what HPDCs cast in aluminum? And thin builts? And then the two covers that you spoke about, outside of this. Are they also aluminum?

DD: They're Magnesium. That's another high-pressure die casting with just the material with about half the aluminum density. So, we get the structure with fewer paths—part of the relentless optimization and mass reduction philosophy.

For the magnesium die-casting, does any load flow through that? Is it structural?

DD: Yeah, it carries a little bit of a load. The covers have some special requirements, and we have periodic inspections that are required.

Do you see any challenges in the mass industrialization of the motorcycle, with the HPDCs being fairly large?

DD: No, because we knew taking on these large castings would involve some technical complexity and risk. We engaged very early in the process with the casting supplier. They are now cutting metal on those tools.

However, they did an extensive analysis and simulation of the mold flow of those tools. The design underwent some iterations to ensure we had a part that could be cast properly. So, we made some tweaks to our design to improve the final product, such as casting through that analysis process, tweaks, and additional analysis.

When you do a monocoque of the battery, if it's such a weight optimization as Damon has done, is the shell of the monocoque enough to carry the load, or load is also passed through the cells, or do you use some structural adhesives?

DD: The cells themselves are isolated from the majority of the loads. Damon has patented the clamshell monocoque in all the major global markets. We are carrying some of the loads through some of the cold plates. We have water-cooled all of the electronics and the battery, and those cold plates are structural components within the system.

JG: An internal and external skeleton.

Are those also aluminum?

DD: That's right.

That's interesting. If you put together the clamshell, there would also be a gasket to join both sides and provide IP67 protection?

DD: Yeah, there's a gasket (that seals the gap between the two halves) material between the clamshells because all of the components and enclosures on the Damon HyperSport have a requirement to be IP6769, which is an ISO waterproof standard.

So we've also built a waterproof motorcycle, which in theory (I wouldn't recommend this in practice) could be submerged underwater without stalling and operate without failure.

Philosophically, this allows you to have much higher confidence in your connectorized stations and enclosures, ensuring that no egress or environmental issues would degrade the vehicle's performance.

JG: I won't suggest we are or are not planning to enter markets beyond motorbikes. But you know, this motor, this battery pack, and the HyperDrive itself—you can imagine it being used in other vehicles for other applications.

Yeah, I was coming to that. I know the HyperSport; the second one is the HyperFighter; they are both premium motorcycles. When do you see yourselves coming down the market to more affordable mid-segment motorcycles?

JG: We can't elucidate future business plans at this stage, but I'm sure you can imagine it, as we've been pointing towards the platform nature of the HyperDrive itself. That is designed for a wide range of motorcycles in the mid-speed, mid-price, mid-range market up to the high-speed, high-price, high-range market.

So, let's say it's the Western market of motorbikes, which they call the middleweight to heavyweight class, in the 500cc to 2000cc equivalent.

We certainly have the desire, aspirations, and internal plans to meet a variety of price points and market segments for all sorts of motorcyclists, from first-timers to experienced riders.

What's fascinating is that of the 3000 or so people who have ordered the Damon bike—the HyperSport or the Hyperfighter, which are, by and large, high-performance machines for experienced riders—24% are people who don't ride. A percentage are people who don't have a motorcycle license.

If you think about the Achilles heel of the motorcycle industry, it's safety, or lack thereof. In one way or another, the lack of safety or lack of attention to the need for people to do things fun but safely really translates in one way or another to people not buying bikes, you know?

So, for every 100 people in Europe and North America, only around 15 ride a motorbike. If motorcycling were safer, the massive untapped potential would grow and explode in the Western Hemisphere.

In India or Indonesia, I'm a motorcyclist surrounded by other motorcyclists in mostly slow-moving traffic. That feels a lot safer than when you're in France or New York, and you're a motorcyclist surrounded by buses, cars, trucks, SUVs, and Cadillac Escalades. So it's different.

The need for safety and attention, the desire for it, is a major decision maker in why people do or don't ride in the Western Hemisphere.

First and foremost, Damon wants to unlock the potential for the future of motorcycling in the West before we tackle the rest of the world. It's a massive undertaking to do that here because of the thesis of needing 200 horsepower and 200 miles of range because of what people here are buying. Their first bike is two or three times more powerful than the common first bike in the rest of the world.

DD: That said, we have done some concept work for smaller vehicles that would be appropriate for the rest of the world.

JG: Largely premised on the HyperDrive design.

DD: Yeah, it is largely premised on the HyperDrive design and achieving performance cost and weight advantages over current approaches. We believe there’s an opportunity to convert tens of millions of people to electric vehicles, and we really can't wait to enter those markets and start doing so.

JG: Absolutely. that's kind of Damon's medium-term plan. Without getting too much into it, we have some tremendous partnerships that we'll be discussing in the future that can lend themselves to expanding or exploring into those markets where 19 out of 20 people ride a motorbike, where it's a way of life and an economic necessity.

But it's still a big passion of people to ride motorbikes out there. First and foremost, by building a world-class superbike that can replace the Ducati or the BMW in your driveway, we can build a brand that can be lusted after and sought after worldwide.

DD: We're also building a first-class company to produce those motorcycles with the quality systems, service, and support needed for products in these markets.

JG: This is where the margins are. Take Yamaha. They produce about 700,000 ‘Western-market-size’ bikes a year and many smaller motorbikes for Southeast Asia and India. They make two or three times the margin on their big bikes.

The big bikes pay for the small bikes. The average person frequently misunderstands this, saying, "Don't you want to be like Volkswagen, who makes arguably more cars than anyone else in the world?"

No, we want to be like Porsche, who bought Volkswagen.

Because Porsche was the most profitable car company in the world.

I wanted to dig deeper into how you came about and where the story started. Derek, before Damon, you were with Alta Motors. What did you create at Alta, and how has that impacted what Damon is doing now?

DD: I was one of the three founders of Alta Motors when we founded it in 2010.

I had started working on an EV motocross motorcycle a few years before with Jeff Sands, a very established product designer in the San Francisco Bay area.

I come from a family of motorcycle racers. I have a professional racing license from the American Motorcyclist Association (AMA) and have done five years of track racing. During that time, we developed our motorcycles to improve their performance.

We always have a saying: if you could, then tune a bike to behave like it was electric. It would perform better on the track. It really means you can make very predictable power delivery.

Electric has peak torque from 0 RPM, not the torque curve of the internal combustion engine, which is always lumpy.

JG: It's funny because peak torque sounds too powerful. It sounds unwieldy and uncontrollable, the opposite of what it should be.

DD: But, it is the opposite. You don't have power that's delivered so weakly at first that you need a transmission to get going. Then, it reaches a power peak earlier than the motor's peak RPM. The power bands get increasingly peaky, and they become less and less rider-friendly.

Electric bikes are the opposite of that. They have peak torque available from 0 RPM. There's no lumpiness; if you design the system correctly, you don't need a sequential transmission. You deliver a seamless riding experience. With a simpler and smoother drivetrain, the rider, the racer, and the commuter all have more control and less distraction from the focus on riding.

I approached Alta from the angle of trying to make a motorcycle with better power delivery. Martin Eberhard (the ex-founder of Tesla) had come across the idea that lithium-ion cells were now produced (at that time) in the low billions of units for laptops. Capable companies were already producing them in really high volume at really high quality.

If you could build an automotive pack out of those cells, that would unlock all these potentials for the auto industry. I wanted to make electric power delivery for motorcycles. I started researching them, which was the genesis of what became Alta.

I have very high standards for what a motorcycle should be, and at the time, I couldn't buy any of the parts to make this motorcycle.

We started the design around an existing aluminum chassis from a motocross bike to understand the geometry and the packaging space. We realized fitting the battery, controller, and motor into that space wasn't feasible.

That turned into a ground-up effort to make a motorcycle. Alta grew to a team of about 50 engineers, and we developed a drivetrain and a high-voltage battery from the ground up. We had success on the race course at a very high professional level.

This came against internal combustion engines. Alta is probably more responsible than any company in this space for pointing to a future where electric motorcycles could not only meet the performance of gas bikes but outperform them in many ways.

I remember that the Redshift's motor peaked at 14,000+ rpm, which was a pretty high number for the time.

Derek Dorresteyn

We did a 14,000 RPM motor and started there because I couldn't buy a motor then. We thought that if you take an industrial motor and improve its cooling, you could exceed its rating for these peak power moments and get a much higher overall performance.

That got me thinking:

Power is ostensibly torque times RPM. With more RPM comes more power.

So, I started researching some of the motors that go into spacecraft, where power density is very high. I found a designer, and we started kicking around some ideas. He did the magnetic part of the motor design.

This is the part where you size the windings, figure out the winding configuration, and then the rotor magnet configuration.

We designed an AC induction motor—a surface-mount permanent magnet (SMPM) motor. We also did a similar design for an interior permanent magnet (IPM) motor, but the SMPM motor had the highest performance by far.

That Alta, including a gear reduction and the first prototype, had a 12,000 RPM motor, which we eventually turned into 14,000 RPM. We achieved a high power of 50 hp, and thanks to the gear reduction, there was very high torque at the shaft with a very low weight - that motor was approximately 6 kg.

Most present-day motors don't compare to that.

DD: That's right. It's interesting to see that most two-wheel motors are hub motors. They are simple implementations. But they're very poor in torque and power density. They don't cool well; you end up with a larger motor than you could have if you had better cooling. Getting any gear reduction is complicated because they have internal winding and external magnets on a hub motor configuration.

So you're not taking advantage of the benefits of high speed and have another weight penalty. The power density is a fraction.

JG: Because of their cost and simplicity, they're suitable for simple low-speed applications, where unsprung weight and mass aren't that big of a penalty.

DD: It's all about cost - that's the only argument you could make for that motor.

Insight EV tracks more than 220 electric mobility players and the world’s most important 2W markets. Connect with us on X at @editor_ev